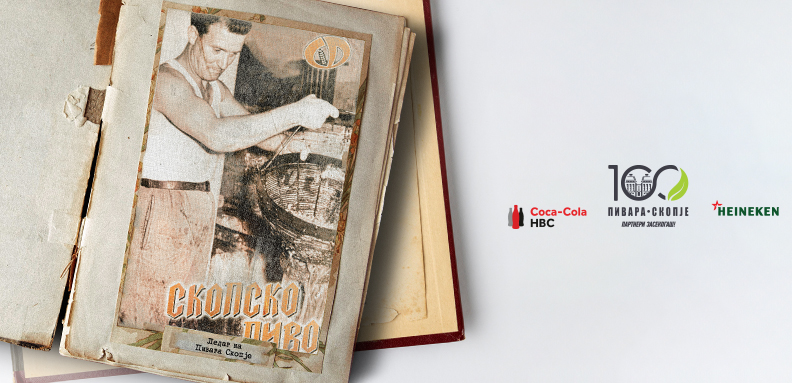

THE ICE MAKERS OF PIVARA SKOPJE

Poured from

Vasilka Dimitrovska, M.Sc

Alexander Madzovski

HAEMUS – Center for scientific research and promotion of culture

One of the essential prerequisites for the production of beer, as well as its consumption, is its cooling and storage at a constant optimal temperature. Today, with modern commercial and home electric refrigeration devices, it is an easy and simple process but, in the not so distant past, the beer industry, like all other food industries, depended on a now forgotten profession related to the production and delivery of ice, the popular ice-makers. How important their profession was to industries and households is shown by the very fact that in the second half of the nineteenth century natural ice was the most important export product of the United States, right after cotton.

Until the first years of the twentieth century, ice was obtained naturally. It was collected from frozen rivers and lakes and then cut into blocks with saws. Another way to make ice was to pour water into molds and let it freeze in the cold winter temperatures. Then the ice was blown with the help of carts, or it was stored in cold underground rooms, where straw or cork was used as insulation material. This method was dominant in the Balkans until the twentieth century, when ice began to be produced mechanically, with the help of engines, primarily for the needs of breweries, which were gaining more and more popularity.

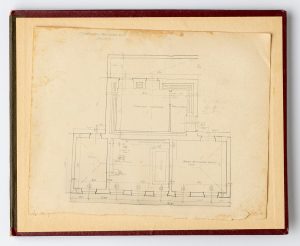

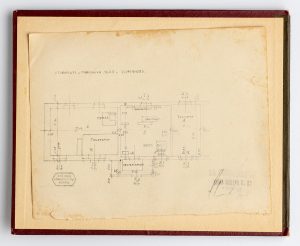

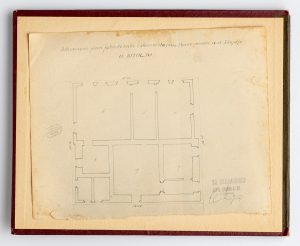

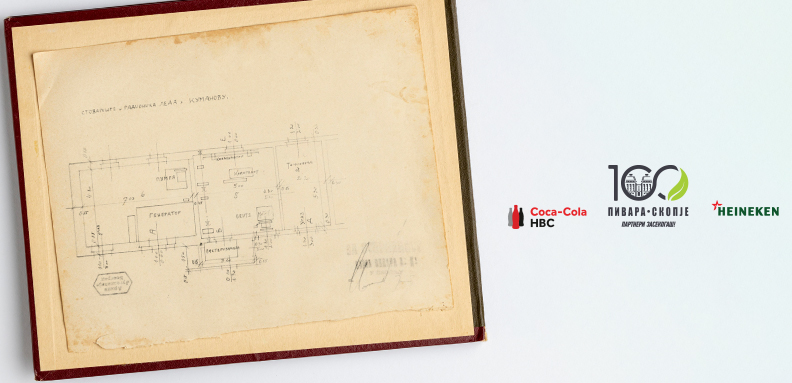

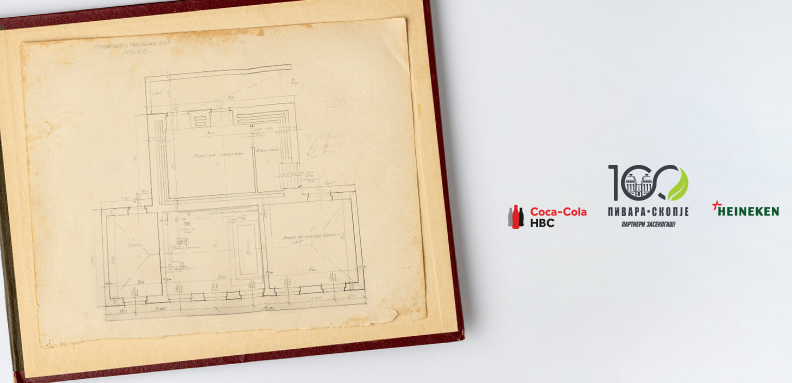

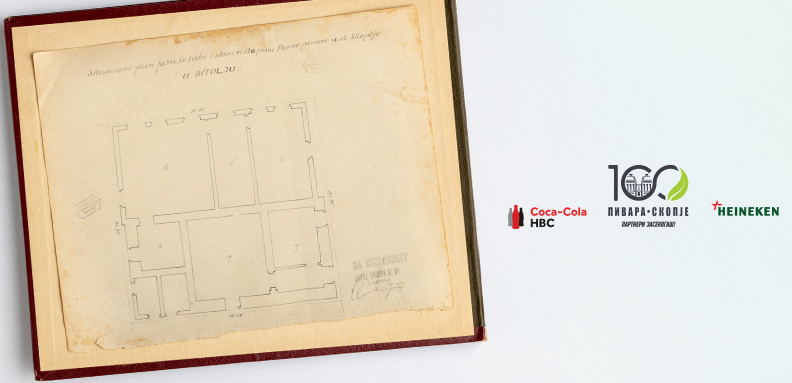

Plans for the ice production facilities of Pivara Skopje in Prilep, Kumanovo and Bitola (1930s)

Among the first investments of any brewery at that time was to provide its own ice production facility. Such was the case with Pivara Skopje, founded way back in 1922. Even at the founding assembly itself, the question of building ice plants was raised, as can be seen from the preserved goals and rules of the joint stock company “Parna Pivara AD” in Skopje.

Pivara Skopje started producing beer in August 1924, and together with that the ice production plant started. As warehouses were opened in other cities in the region served by Parna Pivara AD, ice cream parlors were also opened in them. The company did not register its ice makers as separate companies, but treated them as an integral part of the warehouses and as auxiliary workshops. They had their own address, telephone number and telegraphic address for direct communication with consumers.

Apart from Skopje, Parna Pivara AD had its own ice plants in Bitola, Prilep, Kosovska Mitrovica and Kumanovo. We learn this not only from archival documents, but also from advertisements in daily newspapers of the time, such as the newspaper “Vardar”, which was printed in Skopje between the two world wars. Each ice facility had at least one depository – a person in charge of smooth functioning of the plant and maintaining communication with the headquarters in Skopje. The depositor was the only long-term employee in the regional ice creameries of Parna Pivara AD, and the rest of the workers were hired seasonally for the period from May to September. The ice that was produced in the cooling installations was mainly used to cool the beer. The surplus that remained was sold for the needs of other food industries.

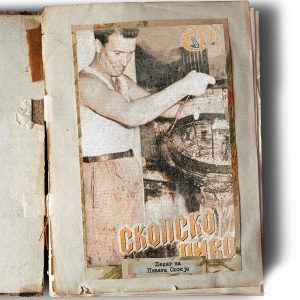

Advertisement for beer and ice creams of Pivara Skopje from 1932 in the daily newspaper “Vardar”, which was published in the period between the two world wars in Skopje

The ice production buildings consisted of: a tap room, an engine and compressor room, a generator and pump room, as well as a beer storage cellar. In the taprooms there was a device for washing the bottles, a device for pouring the beer into bottles, a machine for closing the bottles with aluminum caps, as well as a pasteurization device. In each of the ice houses, in addition to the drive capacities, there was also an office space for the depository, as well as a living space in which he lived together with his family. There were also auxiliary rooms such as a shed for storing barrels and chests, as well as a stable and a locksmith’s workshop. The ice makers had their own carts with which the beer was distributed.

During the eight-hour working hours, the ice makers produced up to a hundred slabs of ice per day, each weighing 15 kg.

Most of the ice cream parlors of Parna Pivara AD – Skopje operated until the Second World War, and some of them continued to exist even years later. Such is the case with the ice factory in Kumanovo, whose balance of production and profit was recorded in a report in the Official Gazette of the People’s Republic of Macedonia from 1956. This icehouse with warehouse of Pivara Skopje located on ul. 1 May in Kumanovo, functioned until the late 1980s of the 20th century.

The text is adapted and reworked from the original research project of HAEMUS entitled “Study on the history of Parnata Pivara AD Skopje”, commissioned and supported by Pivara Skopje.

Prepared by: Vasilka Dimitrovska, M.Sc., Aleksandar Madzovski

Photo: Archives of Pivara Skopje, Archives of Yugoslavia (Belgrade, Serbia), private family archives

Archive source: NUB “St. Kliment Ohridski” – Skopje, DARMS – Department Skopje (Archives of the City of Skopje), Archives of Pivara Skopje, Official Gazette of the NRM, Archives of Yugoslavia (Belgrade, Serbia).